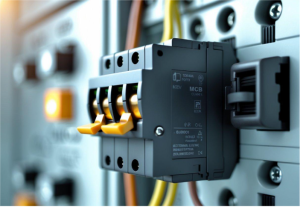

A Miniature Circuit Breaker (MCB) is an essential component of contemporary electrical systems because it serves as a safety mechanism and automatically shuts off electrical circuits in the event of overloads or short circuits. By interrupting the flow of excess current to prevent damage and hazards, this switch safeguards low voltage circuits and ensures reliable operation. MCBs operate using two primary methods: thermal and electromagnetic mechanisms. The electromagnetic part quickly responds to short circuits by moving a plunger that breaks the circuit, while the thermal part uses a bimetallic strip that bends when heated by too much current. This dual action allows MCBs to provide efficient protection compared to traditional fuses.

As the world becomes more reliant on electricity, understanding MCBs’ roles and functions is increasingly important. They not only make electrical installations safer, but they also make it easier to get power back on after a fault.

What Is an MCB? Definition and Core Functions

A Miniature Circuit Breaker, or MCB for short, is an essential component of circuit protection and electrical safety. When it detects overload or short circuits, it automatically stops the flow of electricity, protecting wiring and appliances from damage.

MCB Meaning and MCB Definition

Miniature Circuit Breaker is referred to as an MCB. It is an electrical switch that is made to automatically cut off an electrical circuit when something bad happens, like an overload or a short circuit. The consumer units or breaker panels of homes and businesses typically contain these devices. The MCB moves quickly to protect circuits and devices when the current exceeds its predetermined limit.

Fundamental Role in Electrical Safety

An MCB’s primary function is to reduce the risk of electrical accidents brought on by excessive current. It continuously monitors the flow of electricity and immediately interrupts the circuit when it detects irregularities, such as excessive current due to a fault.

MCB vs. Traditional Fuses and Advantages

Comparing MCBs to traditional fuses reveals several key advantages. Fuses operate by melting a metal wire when excessive current flows, requiring replacement after a fault. In contrast, MCBs use a more sophisticated mechanism, making them more reliable.

Advantages of MCBs:

User-Friendly Reset: It can be reactivated by flipping a switch after tripping, making repairs simpler.

Fault Identification: The position of the switch indicates whether the MCB is on, off, or tripped, making troubleshooting easier.

Because of these features, MCBs are the most popular choice for modern electrical installations because they significantly increase electrical safety and ease of use.

Working Principle: How Does an MCB Operate?

Miniature Circuit Breaker (MCB) operates through detailed mechanisms that detect overloads and short circuits. This section explains how these mechanisms work, focusing on the overload and short circuit protection tripping techniques.

Overview of the Tripping Mechanism

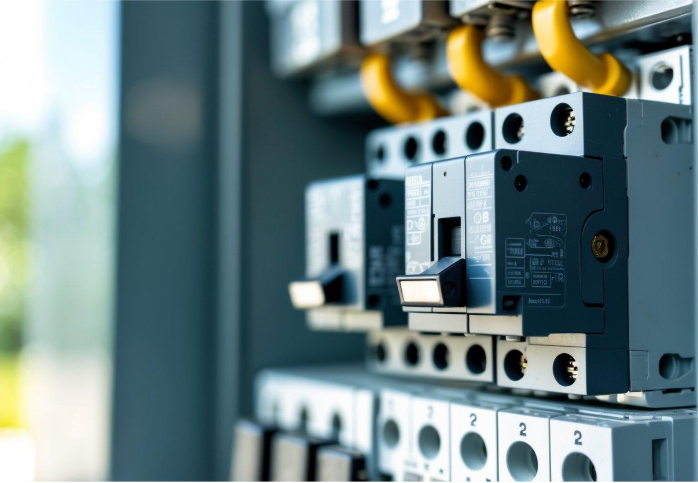

In abnormal circumstances, an MCB uses a tripping mechanism to stop the flow of electricity. This mechanism generally consists of two parts: a thermal trip for overload situations and a magnetic trip for short circuits. This mechanism releases the holding force on the circuit, allowing the moving contact to separate from the fixed contact, which breaks the circuit.

The trip unit is very important in detecting the problem. It might have a magnetic coil and a bimetallic strip for quick detection of short circuits and thermal trips. By combining both methods, the MCB ensures effective circuit protection.

Overload Protection via Bimetallic Strip

The trip unit of the MCB uses a bimetallic strip for overload protection. The strip heats up and bends when the electrical current exceeds a limit. The moving contact separates from the fixed contact as the plunger moves. The bimetallic strip ensures that it does not trip during brief surges by responding to prolonged overload conditions.

Short Circuit Protection and Magnetic Tripping

A strong magnetic field is created in the magnetic coil when there is a short circuit because of the sudden surge in current. The tripping mechanism is almost instantly triggered by this field.This quick response is vital for preventing damage to the electrical system. The arc chute and runner in the MCB assist in managing the arc created when the contacts separate. The arc splitters within these components divide the arc, allowing it to cool and extinguish quickly.

Ratings, Selection, and Applications

To ensure optimal performance and safety in electrical systems, it is essential to comprehend the ratings and selection process of MCBs. The most important aspects of rated current, inrush current, and selecting the appropriate MCB for various applications are discussed in this section.

Rated Current and Inrush Current Considerations

Rated current indicates the maximum current an MCB can handle continuously without tripping. Choosing an MCB with a rated current that is equal to or slightly higher than the load requirement is critical. Inrush current refers to the sudden surge of current that occurs when electrical devices start. The usual operational current may be several times higher than this. MCBs must deal with this brief increase without tripping. Understanding both rated and inrush current helps prevent nuisance tripping while ensuring protection against overload conditions.

Common Applications and Installation Points

- MCBs are versatile devices suitable for various applications. Common uses include:

- Socket Outlets: Ensure safety for general-purpose outlets used in residences and offices.

- Motor Protection: Ideal for small motors and inductive loads, particularly in commercial facilities.

When installing MCBs in a distribution board or consumer unit, using the correct number of poles is key. Each application must reflect on the required standards, ensuring the MCB can effectively interrupt excessive currents while accommodating inrush demands. Proper installation and matching specifications are vital for reliable operation and safety.