Describe root cause analysis

Root Cause Analysis is a methodical approach to problem-solving. Its goal is to find the basic, underlying causes of an issue rather than only treating its visible symptoms. The ultimate objective is to put solutions in place that stop the problem from occurring again.

Beyond Blame: The Fundamental Mentality

The focus should be on “what” and “why” the system failed, rather than “who” made a mistake. Assigning responsibility to particular individuals encourages them to hide errors, which prevents you from recognizing the actual, systemic problems that enabled the problem.

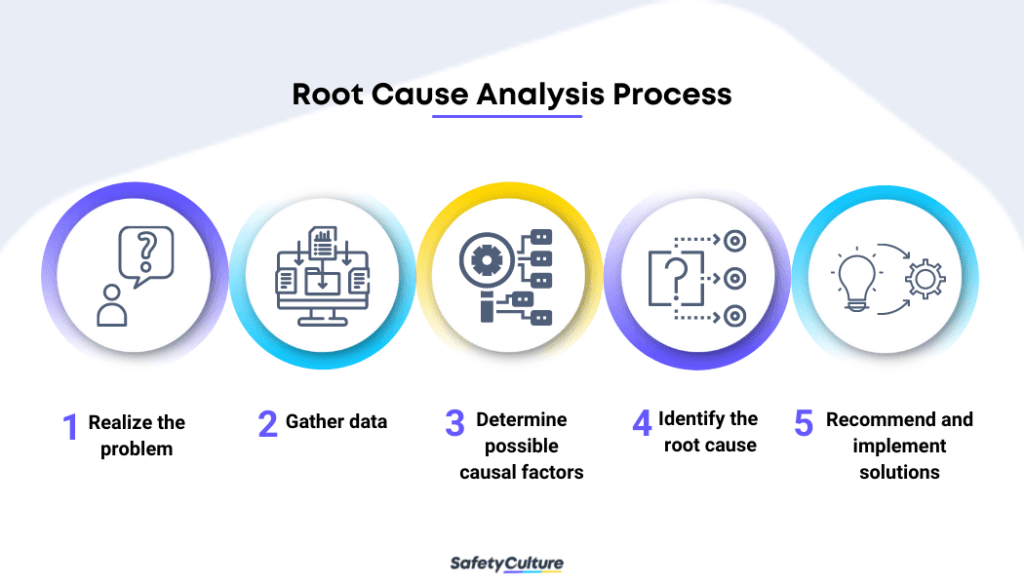

The Methodical Procedure

Clearly defining the problem is the first step in the RCA process. A well-written problem statement pinpoints the exact deviation, its location, and its impact without suggesting a cause or a solution.

Next, compile all pertinent information. Collect evidence, logs, and records. Interview people who were involved and create a detailed timeline of what happened. This factual foundation prevents quick decisions and is necessary for an accurate analysis.

Finding the Causes

Determine every potential contributing element using the available data. These are the events, circumstances, or behaviors that led to the issue. To generate ideas for causes in areas such as Methods, Machines, Materials, People, and Environment, utilize a tool such as a Fishbone Diagram.

How to Apply the “Five Whys”

You can find the root reason by using the “Five Whys” technique. Start by determining the problem and posing the question, “Why did this happen?” After you get that answer, ask “Why?” again. Iteratively repeat this process until you are unable to respond any more; this last step is probably a root cause at the system or process level.

Putting Effective Solutions into Practice

Developing and putting into practice solutions is the next crucial stage. In addition to being workable, lasting, and verifiable, effective solutions should directly address the underlying issues. Make a distinction between preventive measures (using the lesson elsewhere), corrective measures (removing the root cause), and intermediate remedies (containment).

Confirmation and Dissemination

Lastly, confirm the efficacy of the solution and communicate the results. Make sure the issue has been properly fixed and hasn’t led to any new problems by following up. Share the knowledge gained throughout the company to change policies, training, and designs and stop the issue from happening again.

Examples from the real world: The significance of addressing the underlying reasons

Moving past band-aid solutions requires addressing the underlying problems. Treating a problem’s symptoms alone only offers temporary solutions. The fundamental problem persists, ensuring that it will reappear, frequently with more severe repercussions.

It leads to true and lasting improvement. A permanent remedy is produced by removing the problem’s underlying cause. By doing this, the frustration, wasted work, and ongoing expenses that come with dealing with the same problem over and over again are avoided.

This method creates systems that are more robust and dependable. Redesigning a tool, upgrading training, or enhancing a process are frequently necessary to address the underlying reason. This fortifies the system as a whole, increasing its resistance to a wide range of potential issues.

It encourages a culture of prevention and ongoing learning. An organization transitions from reactive firefighting to proactive problem-solving when it concentrates on core causes. This way of thinking promotes more thorough investigation and dedication to averting mistakes before they occur.

Ultimately, it saves significant resources. While a root cause analysis requires an initial investment of time and effort, it is far cheaper than the endless cycle of addressing the same symptoms. It conserves money, time, and morale in the long run

Reasons & benefits: why perform root cause analysis

Here are the reasons and benefits for performing a Root Cause Analysis

To Prevent Recurrence

The primary reason for RCA is to prevent the same problem from happening again. Treating only the symptoms leads to a cycle of repeated failures. Addressing the root cause breaks this cycle permanently.

To Reduce Costs

Repeated problems are expensive. They consume resources for repairs, cause downtime, and waste materials. RCA identifies the source of these costs, allowing for a one-time investment in a solution that eliminates future expenses.

To Improve Safety

RCA is crucial in settings where safety is a top priority. It reveals latent system flaws and procedural weaknesses that made an incident possible. By addressing these underlying causes, individuals are protected, injuries are avoided, and lives are saved.

To Enhance Quality

Consistently high quality requires robust processes.RCA assists in finding flaws in these procedures that result in errors. Organizations might increase the dependability and caliber of their outputs by fortifying the underlying system.

To Foster a Proactive Culture

An organization’s perspective is changed from reactive firefighting to proactive prevention through RCA. By encouraging teams to search more thoroughly for systemic problems, it transforms challenges into chances for significant advancement.

To Promote Organizational Learning

RCA is a powerful learning tool.It establishes a structured procedure for looking into mistakes without assigning blame. By disseminating the acquired knowledge throughout the company, similar problems can be avoided in other departments.

To Boost Productivity

You can eliminate a continuous source of disruption and rework by addressing the underlying cause of an issue. This simplifies processes, frees up staff members’ time, and enables them to concentrate on activities that bring value rather than troubleshooting repeatedly.

To Make Decisions Based on Data

RCA is based on data and evidence, not conjecture or speculation. Based on a thorough understanding of the issue, this results in more effective solutions and guarantees that resources are allocated to remedies that will genuinely work.

Step 1: Define the Problem

Clearly identify and describe the issue you are facing. Be specific about what the problem is, its magnitude, and its impact. A well-defined problem statement sets the stage for the entire investigation.

- Ask: What exactly is happening? Where and when did it occur? What is the scope and impact?

Step 2: Gather Data and Evidence

Collect all relevant information about the problem before, during, and after the event. This includes logs, records, photographs, physical evidence, and interviews with everyone involved.

- Ask: What data do we need? Who has information about this event? What does the evidence tell us?

Step 3: Identify Possible Causal Factors

List all the conditions, actions, or inactions that contributed to the problem. This is a brainstorming step to map out the sequence of events and the context in which the failure occurred.

- Tool: Use a Timeline to chart the event sequence and a Fishbone Diagram (Ishikawa) to brainstorm causes in categories like People, Methods, Machines, Materials, Environment, and Management.

Step 4: Identify the Root Cause(s)

This is the core of the analysis. Drill down from the causal factors to find the fundamental, underlying process or system failure.

- Tool: Use the 5 Whys technique. For each causal factor, ask “Why?” repeatedly until you can no longer answer. The final answer is typically a root cause.

Step 5: Develop and Implement Solutions

Create corrective actions that directly address the root causes you identified. Solutions should be effective, feasible, and sustainable.

- Ask: What action will prevent this root cause? Who will do it? By when? How will we implement it?

Step 6: Implement and Verify Effectiveness

Put the solutions into action. The most critical part of this step is to follow up and monitor the situation to ensure the solutions are working and the problem has not recurred.

- Ask: Did we implement the solution correctly? Is the problem solved? Are there any unintended consequences?

Step 7: Share the Findings and Standardize

Communicate the results of the RCA to all relevant parties. Update procedures, training manuals, and designs to embed the new knowledge into the organization and prevent the problem anywhere else.

- Ask: Who else needs to know this? What processes or documents need to be updated? How can we prevent this across the organization?

This structured approach ensures you move beyond symptoms to create lasting solutions that improve your systems and prevent future problems.

How to conduct Root Cause Analysis: Step by step in short paragraphs

Of course. Here is a step-by-step guide to conducting a Root Cause Analysis in short, focused paragraphs.

Step 1: Define the Problem Clearly

Begin by writing a precise problem statement. Describe what is wrong, its location, timing, and impact. A clear definition ensures everyone is solving the same problem and prevents misdirected effort.

Step 2: Collect All Relevant Data

Gather evidence immediately. This includes physical evidence, data logs, process documents, and firsthand accounts from involved personnel. This factual foundation is critical for an accurate analysis and prevents assumptions.

Step 3: Map the Timeline of Events

Chronologically sequence every action and condition leading up to, during, and after the event. This visual map helps identify where the process failed and reveals contributing factors that may otherwise be overlooked.

Step 4: Identify Causal Factors

Brainstorm all the immediate causes that contributed to the problem. Consider categories like human error, equipment failure, procedural gaps, environmental conditions, and management systems. This step creates a list of potential targets for deeper investigation.

Step 5: Drill Down to the Root Cause

For each causal factor, apply the “5 Whys” technique. Repeatedly ask “Why?” until you reach the fundamental process or system failure that allowed the problem to occur. This is the core of the analysis.

Step 6: Develop Effective Solutions

Create corrective actions that directly address the identified root causes. Solutions must be practical, sustainable, and designed to prevent recurrence, not just treat the symptoms.

Step 7: Implement and Verify the Fix

Put the solutions into action and assign ownership. Most importantly, monitor the results over time to confirm the problem is truly resolved and has not created new issues elsewhere.

Step 8: Standardize and Share Learnings

Update standard operating procedures, training materials, and designs to reflect the new solution. Communicate the findings across the organization to prevent the same problem from happening in other areas.

Best practices for RCA

To conduct root cause analysis effectively, consider these best practices.

Focus on Systems and Processes, Not People

The goal of RCA is to improve systems, not assign blame. Human error is often a symptom of a deeper system failure, like inadequate training, unclear procedures, or poor design. A blameless culture encourages transparency and honest reporting, which is essential for accurate analysis.

Use a Cross-Functional Team

Assemble a team with diverse perspectives, including those who do the work, manage the process, and maintain the equipment. This ensures a comprehensive view of the problem and challenges assumptions that a single person might miss, leading to more robust conclusions.

Base Conclusions on Objective Evidence

Root causes must be verified by data, not opinions or hearsay. Evidence can include data logs, photos, measurements, and confirmed witness statements. This practice ensures your solutions address the actual problem, not just a perceived one.

Examine the “5 Whys” in greater detail.

Rarely is the initial “why” response the underlying cause. Asking “why?” repeatedly (usually five times or more) compels the team to look past symptoms and superficial justifications in order to identify the underlying process or system failure.

Consider a Variety of Causes

The majority of issues have multiple underlying causes that fall into various categories. Instead of focusing on a single cause, a comprehensive RCA should find aspects pertaining to equipment design, management systems, training, communication, and procedures.training, communication, equipment design, and management systems, rather than settling for a single cause.

Prioritize effective and sustainable solutions.

Corrective actions that target the root cause and are practical to implement are the most successful. They should be long-lasting, which means that they are not just a temporary fix but rather are integrated into the process through design changes, training, or revised procedures.

Check the Solutions’ Effectiveness

An RCA is not complete once a solution has been implemented. You must closely monitor the process to ensure that the problem has been fixed and hasn’t resulted in any new issues. Verifying that the analysis was successful requires this follow-up.

Distribute the Results Organization-Wide

Lessons learned throughout the company are what give an RCA its full worth. Transform a local remedy into a systemic improvement by sharing the underlying reasons and answers with other departments and teams to stop similar issues from happening elsewhere.

Conclusion

Root cause analysis is a crucial procedure for determining why something in your infrastructure—whether it be the people, technology, or procedures—went wrong or why something performed well. Although it takes time and work to set up an efficient RCA process, the results will be more accurate and long-lasting problem solving as well as the creation of the circumstances required for optimal infrastructure performance.